Your current position:Home>>Copper molybdenum

Email:ebiz@ctia.com.cn

Copper molybdenum

Copper molybdenum

Molybdenum products are important in the missile industry, where it is used for high-temperature structural parts, such as nozzles, leading edges of control surfaces, support vanes, struts, reentry cones, heal-radiation shields, heat sinks, turbine wheels, and pumps.

Molybdenum products have also been useful in the nuclear, chemical, glass, and metallizing industries. Service temperatures, for molybdenum alloys in structural applications arc, are limited to a maximum of about 1650'C (3000'F). Pure molybdenum has good resistance to hydrochloric acid and is used for acid service in chemical process industries.

Molybdenum material are used in the following industries: glass melting, vacuum furnace, vacuum deposition, aerospace, solar,nuclear, electronics,automotive, and medical.

We carry molybdenum in wire, rod, sheet, and plate. We also sellmolybdenum nuts, bolts, heat shields, and other hardware for vacuumfurnace and high vacuum environments.

We carry molybdenum in wire, rod, sheet, and plate. We also sellmolybdenum nuts, bolts, heat shields, and other hardware for vacuumfurnace and high vacuum environments.

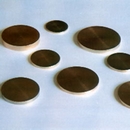

1, Grade: Mo85Cu15, Mo70Cu30, Mo60Cu40, Mo50Cu50

2, Length: 5mm-300mm

3, Width: 5mm-300mm

4, Thickness: 0.1mm-5.0mm

5, Semi-finished or finished (Ni/Au plated) products available

2, Length: 5mm-300mm

3, Width: 5mm-300mm

4, Thickness: 0.1mm-5.0mm

5, Semi-finished or finished (Ni/Au plated) products available

Copper molybdenum high performance composites are fabricated from carefully controlled porous Molybdenum that is vacuum infiltrated with molten copper. This results in a MoCu composite that has high conductivity and a matched low thermal expansion for heat sinks.

Composition: Mo 50%, Cu 50%

Density: 9.4g/cm3

Coefficient of Thermal Expansion (10-6/K): 9.8

Thermal Conductivity (W/mK): 245

Specific Heat Capacity (J/kgK): 320

Length: 5mm-300mm, Width: 5mm-300mm, Thickness: 0.1mm-5.0mm

Density: 9.4g/cm3

Coefficient of Thermal Expansion (10-6/K): 9.8

Thermal Conductivity (W/mK): 245

Specific Heat Capacity (J/kgK): 320

Length: 5mm-300mm, Width: 5mm-300mm, Thickness: 0.1mm-5.0mm

Composition: Mo 60%, Cu 40%

Density: 9.5g/cm3

Coefficient of Thermal Expansion (10-6/K): 8.7

Thermal Conductivity (W/mK): 215

Specific Heat Capacity (J/kgK): 310

Length: 5mm-300mm, Width: 5mm-300mm, Thickness: 0.1mm-5.0mm

Density: 9.5g/cm3

Coefficient of Thermal Expansion (10-6/K): 8.7

Thermal Conductivity (W/mK): 215

Specific Heat Capacity (J/kgK): 310

Length: 5mm-300mm, Width: 5mm-300mm, Thickness: 0.1mm-5.0mm

Composition: Mo 70%, Cu 30%

Density: 9.6g/cm3

Coefficient of Thermal Expansion (10-6/K): 7.5

Thermal Conductivity (W/mK): 190

Specific Heat Capacity (J/kgK): 300

Length: 5mm-300mm, Width: 5mm-300mm, Thickness: 0.1mm-5.0mm

Density: 9.6g/cm3

Coefficient of Thermal Expansion (10-6/K): 7.5

Thermal Conductivity (W/mK): 190

Specific Heat Capacity (J/kgK): 300

Length: 5mm-300mm, Width: 5mm-300mm, Thickness: 0.1mm-5.0mm

Composition: Mo 85%, Cu 15%

Density: 10.0g/cm3

Coefficient of Thermal Expansion (10-6/K): 6.3

Thermal Conductivity (W/mK): 160

Specific Heat Capacity (J/kgK): 275

Length: 5mm-300mm, Width: 5mm-300mm, Thickness: 0.1mm-5.0mm

Density: 10.0g/cm3

Coefficient of Thermal Expansion (10-6/K): 6.3

Thermal Conductivity (W/mK): 160

Specific Heat Capacity (J/kgK): 275

Length: 5mm-300mm, Width: 5mm-300mm, Thickness: 0.1mm-5.0mm

Cu/Mo/Cu (CMC) is a sandwich composite including a molybdenum core layer and two copper clad layers. It has tailorable CTE, high thermal conductivity and high strength. All types of Cu/Mo/Cu sheets can be stamped into components.

Cu/Mo70Cu/Cu (CPC) is a sandwich composite like Cu/Mo/Cu including a Mo70-Cu alloy core layer and two copper clad layers. The ratio of the thickness in Cu:Mo-Cu:Cu is 1:4:1. It has different CTE in X and Y direction, higher thermal conductivity than that of W(Mo)-Cu, Cu/Mo/Cu and more cheap. All types of Cu/Mo70Cu/Cu sheets can be stamped into components.

1, width×Length: (2.0-100.0mm)×(2.0-100.0mm)

2, High: 50-2000mm

3, Density: 10.15g/cm3

4,Grade: Mo-1、Mo-2、Mo-4

5,Applications: The color of surface of the Molybdenum bar is silver-grey, and mainly used in drawing thin Molybdenum wire, Molybdenum electrode and steel-making additives.

The finished molybdenum crucible is made by rolled high temperature molybdenum plate with the excellent characters of strength and high temperature resistance. It’s orderly and tidily profiled and well welded in order to ensure the boat having a best lifetime under the condition of high temperature and stress.

Four main classes of commercial molybdenum-base alloys exist. The most common of the carbide-strengthened alloys is known as TZM. Other alloys in this class include TZC (1.2% titanium, 0.3% zirconium, 0.1% carbon), MHC (1.2% hafnium, 0.05% carbon), and ZHM (1.2% hafnium, 0.4% zirconium, 0.12% carbon).

Email : ebiz@ctia.com.cn

Copyright©2001 - 2011 CTIA E-biz Center All Rights Reserved

Copyright©2001 - 2011 CTIA E-biz Center All Rights Reserved